Manufacturing processes merge with information technology

Digitization in design and production

The digital way to “Smart Factory”

SCHMEES is excellently positioned in the midmarket. With many clever, innovative minds, we offer the best conditions for digitized design and production. It is more important than ever to realize the opportunities offered by digital change.

For SCHMEES, digital competence is a decisive competitive factor. Intelligent planning and control systems increase productivity and increase the efficiency of business processes. Digital simulations and dimensional checks lead to an increase in precision and are the basis for our high quality standards for our products. New, innovative technologies in production such as additive manufacturing (3D printing) conserve resources and revolutionize the production of complex metal components in the shortest possible time.

The basis for implementation, however, is and remains the employee. As specialists in your field, they are the link between the digital and the real world.

Construction

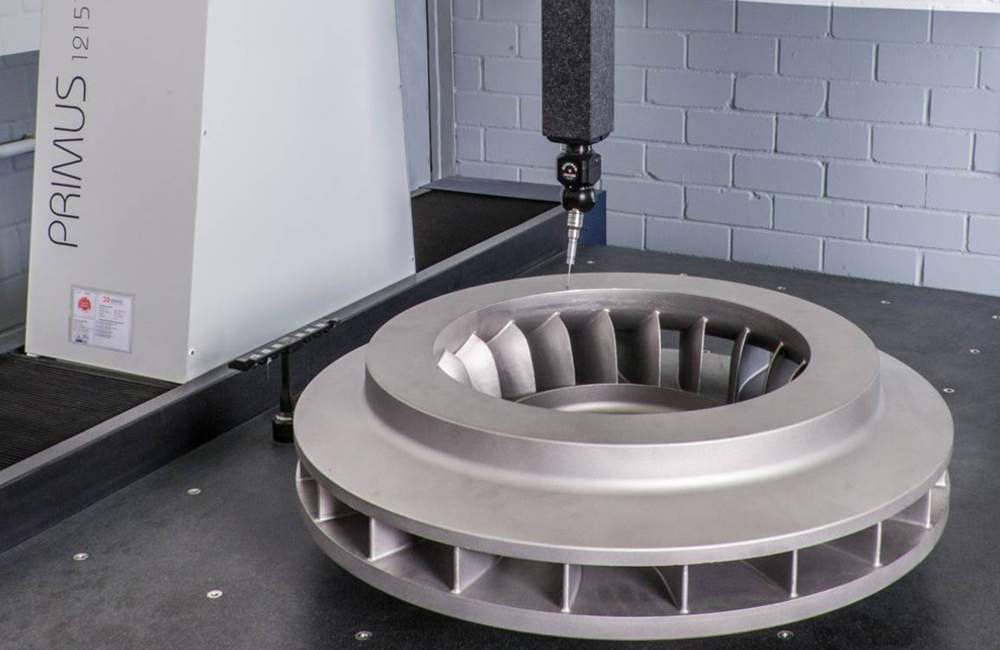

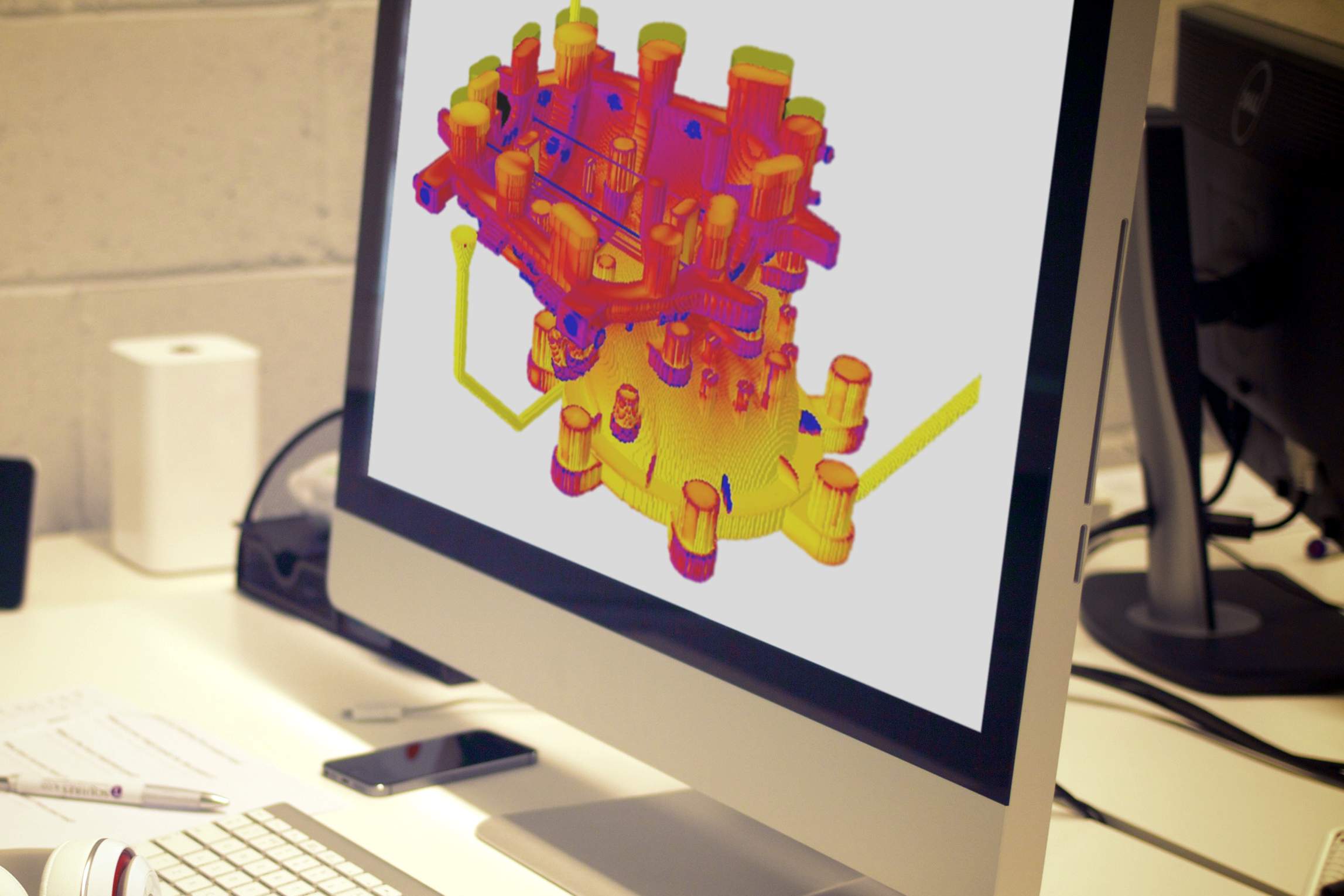

We take over and optimize digital design data and, if required, also engineering and project management. For this purpose, we create 3D designs based on CAD from 2D drawings. In the area of reverse engineering, existing components are digitally measured using laser scanners, scanned and, if necessary, optimized in their topology. Various component properties can already be analysed in the design phase. This includes, for example, the analysis of stress distributions.

We offer our customers a decisive competitive advantage already in the planning phase through well-founded, individual advice and support. The goal is always a result in a class of its own.

Digital technologies in production

As a modern foundry manufactory we have done our homework. We understand the needs and expectations of our customers, optimize existing processes and use new, digital technologies efficiently and sustainably. In cooperation with efficient network partners, we offer additive manufacturing technologies. Our customers receive all products in the usual SCHMEES quality from a single source.

The use of additive technologies and generative manufacturing processes allows us to produce ready-to-use individual parts and initial samples made of steel, stainless steel, titanium and aluminium at short notice. Complex components with undercuts or internal structures can be created from metal using 3D printing.

3D metal printing – Electronic Beam Melting EBM

We offer 3D metal printing in cooperation with our network partner using Electronic Beam Melting (EBM). 3D printing is fast, simple and durable, and we can play with weight, material efficiency and complex structures that challenge creative thinking.

We offer 3D metal printing in cooperation with our network partner using Electronic Beam Melting (EBM). 3D printing is fast, simple and durable, and we can play with weight, material efficiency and complex structures that challenge creative thinking.

Additive manufacturing also offers an extremely fast and cost-effective way to change the design of a product. There is no need to create a new manufacturing workflow. We make a design change using CAD data and send it digitally to the 3D printer.This process is mainly used for functional precision and design samples.

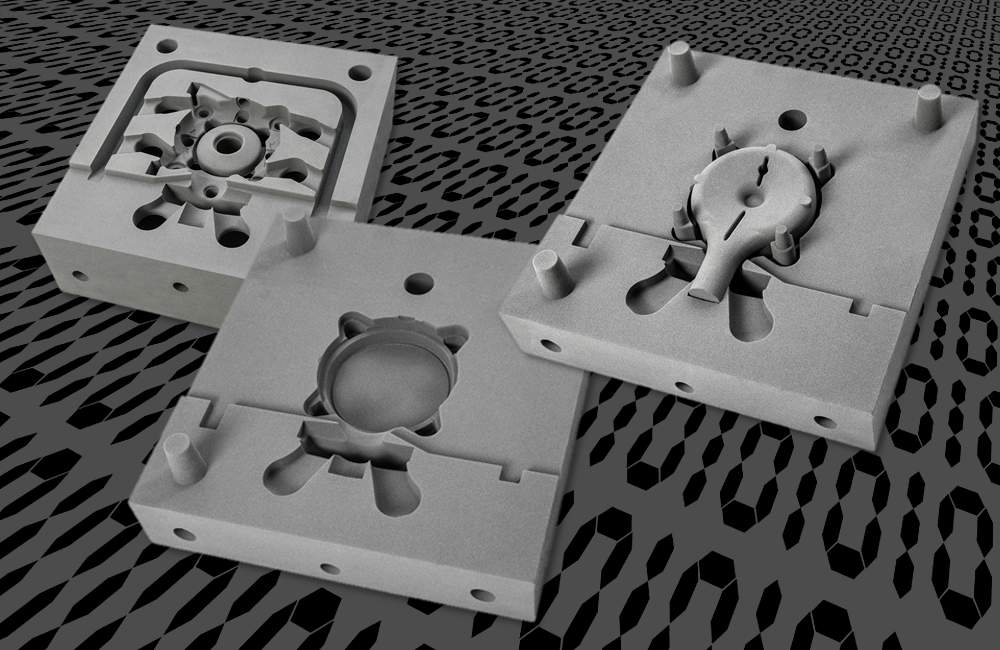

Moulds and cores from the 3D printer for sand and investment casting

In contrast to the conventional production of moulds, in which only the production of model plates or core boxes can take several weeks, even complex sand moulds can be printed in a few days using 3D printing.

In contrast to the conventional production of moulds, in which only the production of model plates or core boxes can take several weeks, even complex sand moulds can be printed in a few days using 3D printing.

In addition to the shortened production time, the design freedom is far less restricted than with conventional production. PMMA models from the 3D printer are suitable for investment casting. For complicated cores with undercuts, such as those found in impellers, we use a combination of conventionally produced molds and 3D-printed cores.

SCHMEES uses the following processes in mold making:

- Polystyrene models (EOS machines – selective laser sintering) are used for investment casting.

- PMMA models (Voxeljet machine – Binderjetting) are used for investment casting when finer surfaces and larger models are required.

- Printed sand moulds (ExOne machine – Binderjetting Sand) are used for large parts.