Quality made of stainless steel

SCHMEES cast is one of the leading international suppliers of stainless steel castings. The company specialises in pump and turbine construction, as well as in the food and pharmaceutical industries.

News from the SCHMEES stainless steel foundry

Another 3D printer for SCHMEES cast Pirna GmbH

At the Gifa 2023 trade fair, we signed a contract for a second S Max Pro 3D sand printer from Exe One. It is expected to arrive this month. This means that we will be able to double our production capacity at the Pirna site as early as July.

With this expansion of our machinery, we are ready to work even more efficiently and innovatively. The S Max Pro printers enable us to print precise, high-quality 3D sand moulds that will further optimise our production processes.

We are excited to be part of the advanced world of 3D sand printing and look forward to serving our customers even more efficiently.

In the picture: Eric Bäder, Managing Director Exe One and Johann Unglaub, Managing Director of SCHMEES cast Pirna GmbH

SCHMEES cast Pirna is official sponsor of the Dresden Monarchs!

Jörg Dreßler, Managing Director of the Dresden Monarchs, and Johann Unglaub, CEO of SCHMEES cast Pirna GmbH, sign a three-year contract.

We are delighted to be able to actively support the Dresden Monarchs as a great ambassador for our region over the next three years. With their consistent and sustainable development strategy and their strong work with young talent, the Monarchs embody a philosophy that fits perfectly with our company’s direction.

We are firmly convinced that with the Dresden Monarchs we are exactly in tune with the spirit of the times. Our employees were delighted with this new commitment, which is very important to us. The footballers have a young and dynamic audience, and we want to present ourselves as an attractive employer in this context. At the same time, we also want to give something back to our region and support the great work of the club.

Beauty in steel: Pirna foundry produces high-gloss sculptures

“They are coveted by collectors from all over the world: the family business SCHMEES cast from Pirna has made a name for itself as a manufacturer of art sculptures. There are now examples in Amsterdam, Rio and even Seoul.”

The video was made available to us with the kind permission of MDR, Mitteldeutscher Rundfunk and Dreifilm GbR – Medienproduktion.

Source: https://www.mdr.de/video/mdr-videos/f/video-668266.html

Castings weighing up to 10 tonnes, including for turbines or pipeline pump housings, are manufactured at our plant in Pirna.

In addition to our day-to-day business, art is an important part of our portfolio, which we serve with great passion. We have made a name for ourselves worldwide as a manufacturer of high-gloss stainless steel sculptures.

Once dismissed as a hobby, art casting is now an important and successful mainstay of SCHMEES.

Although the casting of the sculptures is already a highly complex task, SCHMEES specialises in surface finishing and final processing. Probably a unique selling point in Europe.

The highly polished and reflective surfaces require craftsmanship, patience, an eye for detail and a great deal of experience. This is what characterises SCHMEES and its employees.

The MDR has filmed a short reportage about our art division in Pirna. You can look forward to exciting insights in an interview with Johann Unglaub, Managing Partner of SCHMEES cast Pirna GmbH.

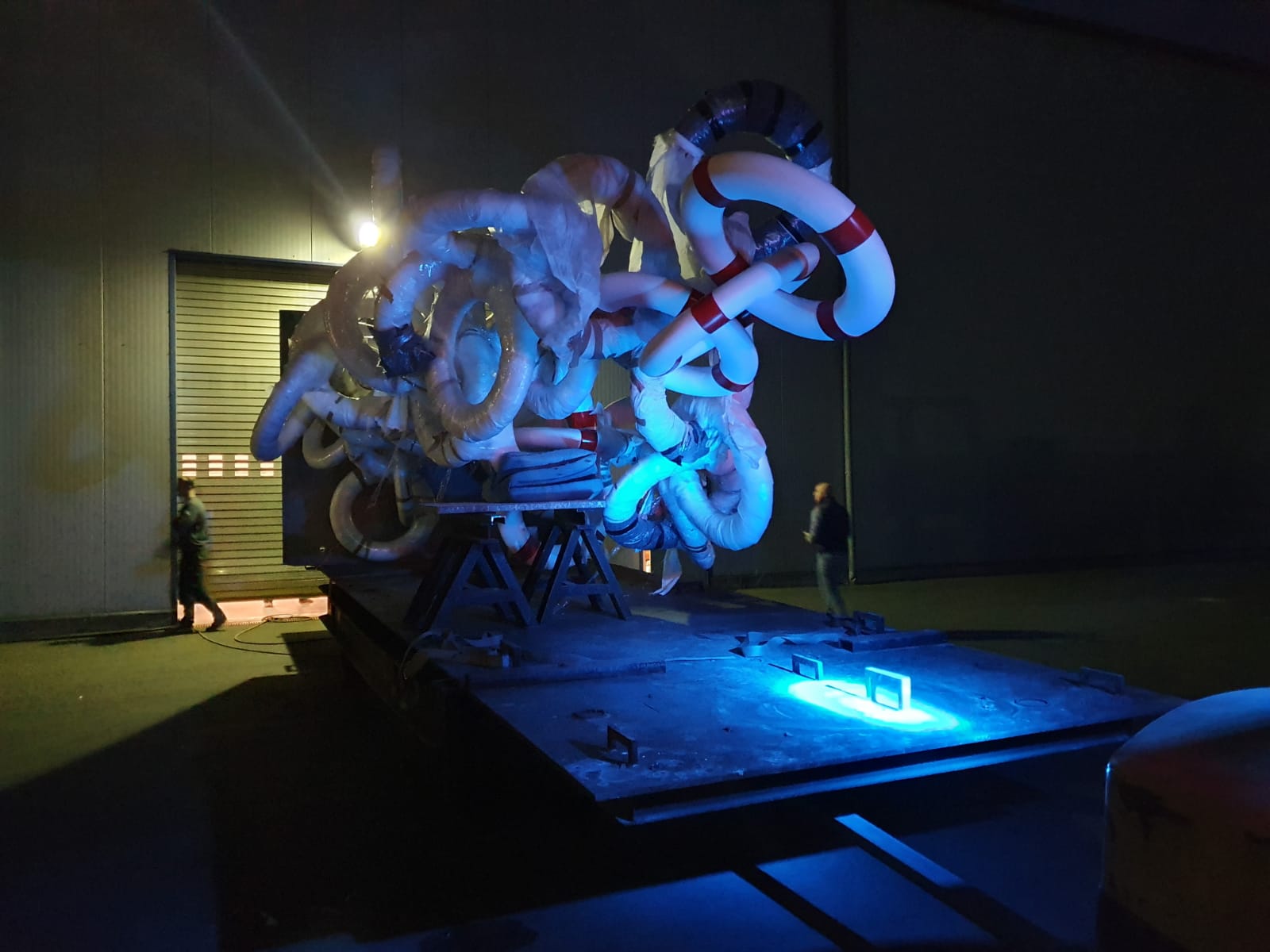

Life Rings – New artwork for Elmgreen & Dragset inaugurated

The 8 metre high sculpture now stands in the Djurgården Sculpture Park in Sweden.

Life Rings” is a new sculpture by the artist duo Elmgreen & Dragset for Princess Estelle’s Cultural Foundation. Life Rings is the second permanent work presented by Princess Estelle’s Cultural Foundation for the Sculpture Park in Djurgården, Stockholm.

The new sculpture was inaugurated on 8 June 2021 at Djurgården during a digital opening ceremony attended by Prince Daniel, artists Michael Elmgreen and Ingar Dragset, Danish Ambassador Vibeke Rovsing Lauritzen, Norwegian Ambassador Christian Syse and Sara Sandström Nilsson from Princess Estelle’s Cultural Foundation.

The entire object was cast in several sections of stainless steel. The interlocking rings placed the highest demands on the planning and in particular the mould construction. The complex moulds were created using state-of-the-art additive technology. Based on 3D data sets, the sand moulds were produced on high-performance binder jet 3D printers.

Further information, links and an interesting video about the sculpture and the artists can be found on SCHMEES art.