Construction and development

Quick production of complex castings made of steel and iron with or without forming tool

To meet the requirements of the market for a cheap and efficient production of prototypes, special serial part or pre-series part, we have founded the company innocast GmbH at the site in Langenfeld, in the year 2003.

The manufacturing of those series made of all steel and iron alloys, as well as bronze, aluminum, brass, needs new and future-oriented technologies. innocast is specialized in manufacturing quick and cheap special series-, functional- or pre-series-parts, whose functionality according to the start of production shall be checked.

At this, different casting processes – according to the special technical needs – like precision casting, ceramic molding or the sand casting, will be used. The use of different production processes in combination to the large number of suitable alloys guarantees the targeted near production-ready product.

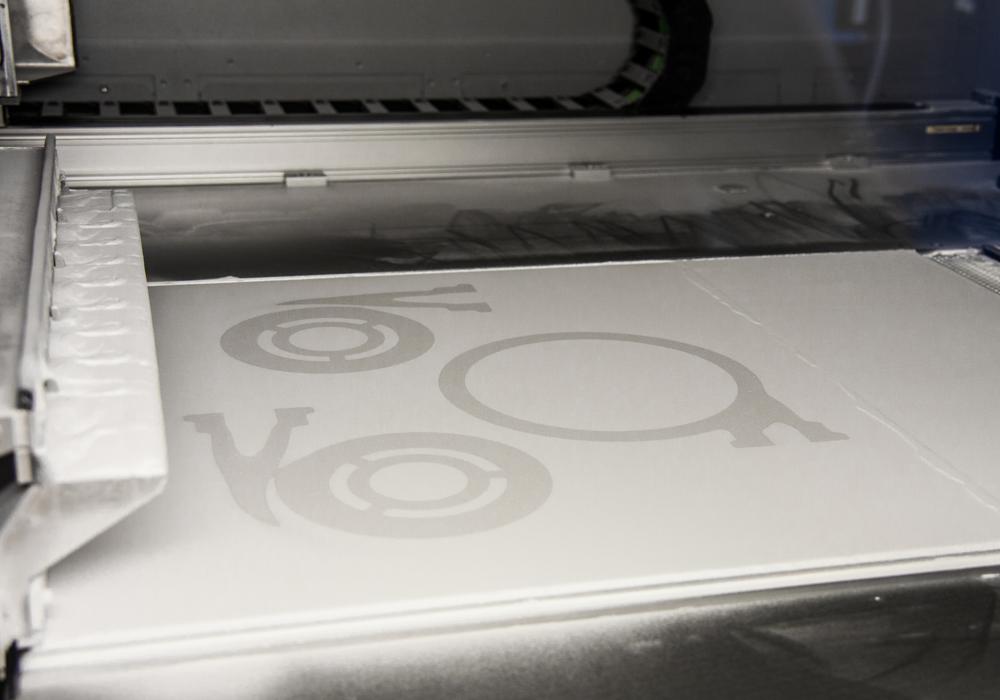

Innovative casting methods for pre-series prototypes

Different casting methohods are used for pre-series prototypes. To see in the turbocharger example to the right.

Those first components can be made out of corresponding 3d-constructions within 10 working days. In comparison to serial production, this is much quicker and cheaper, because the costs of tools are avoided.

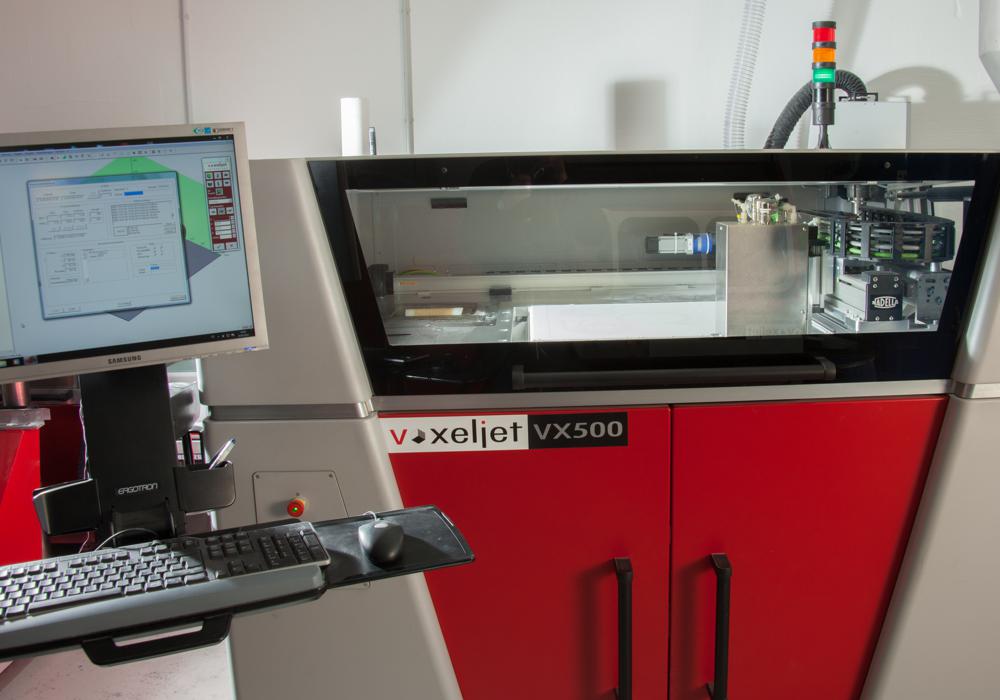

By selecting suitable production (Additive technologies) and the clever combination of technologies provides SCHMEES in collaboration with innocast the decisive customer benefits: fast, precise and flexible.